In today’s competitive manufacturing landscape, precision and efficiency are the driving forces behind successful product development. From automotive components to consumer electronics, countless industries rely on metal stamping to produce durable and accurate parts at scale. To achieve this, selecting the right partner is crucial. A trusted stamping parts supplier not only provides quality components but also ensures consistency, cost-effectiveness, and innovation across projects.

What Is a Stamping Parts Supplier?

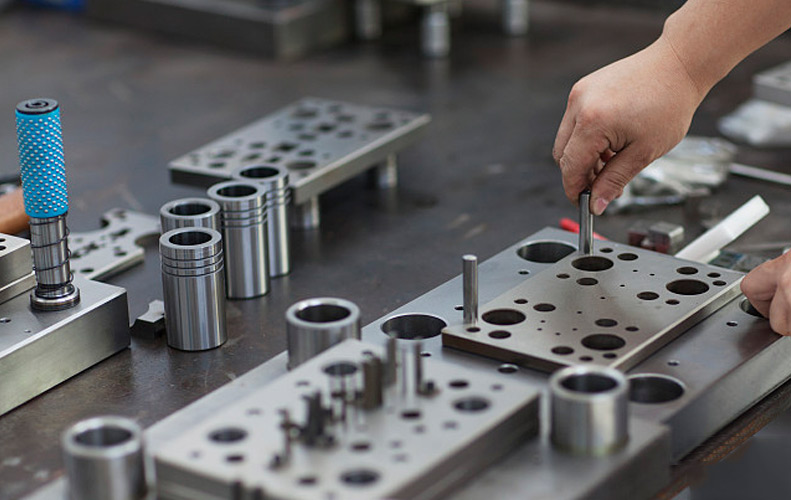

A stamping parts supplier is a specialized company that designs, manufactures, and delivers metal parts using stamping processes such as bending, punching, coining, and embossing. These suppliers convert raw metal sheets into complex shapes that meet precise industrial specifications.

Unlike generic vendors, professional suppliers provide expertise in material selection, prototyping, mass production, and even secondary services like plating, welding, or assembly. Their role extends beyond simply delivering parts—they act as partners who understand the unique needs of each industry.

Why Stamping Is Essential in Modern Manufacturing

Metal stamping is a versatile fabrication method with several advantages, including:

- Speed and Efficiency: High-speed presses produce large volumes of identical parts quickly.

- Accuracy: Consistent results ensure that each part meets exact design specifications.

- Cost-Effectiveness: Bulk production lowers per-unit costs, making it ideal for mass manufacturing.

- Material Flexibility: Stamping works with steel, aluminum, copper, brass, and more.

- Durability: Stamped parts are robust, supporting long-lasting applications.

These benefits make stamping an indispensable method for industries that prioritize performance and reliability.

Industries That Depend on Stamping Parts Suppliers

Automotive Industry

From brackets and engine parts to body panels, stamping is the backbone of automotive production.

Electronics

Precision-stamped connectors, casings, and terminals ensure seamless operation of electronic devices.

Aerospace

Lightweight yet durable stamped parts are essential for safety and efficiency in aircraft design.

Medical Equipment

High-precision components used in surgical instruments and medical devices rely on expert suppliers.

Construction

Stamped parts like fasteners, supports, and fittings provide strength in building and infrastructure projects.

Services Offered by Stamping Parts Suppliers

- Custom Engineering and Design – Suppliers collaborate with clients to create components tailored to specific applications.

- Prototyping – Small-scale prototypes are developed to validate designs before full-scale production.

- High-Volume Manufacturing – Automated stamping presses deliver consistent results for large orders.

- Secondary Processing – Services such as coating, heat treatment, or assembly enhance functionality.

- Quality Control – Rigorous inspections ensure parts meet international standards.

Key Qualities to Look for in a Supplier

Industry Experience

Suppliers with years of experience bring deep knowledge of complex designs and industry regulations.

Advanced Technology

Modern stamping machines and CAD/CAM systems ensure efficiency and precision.

Quality Certifications

Suppliers should adhere to recognized standards such as ISO or industry-specific compliance.

Customization Capabilities

A good supplier offers flexible solutions tailored to each client’s requirements.

Scalability

The ability to manage both small and large production runs demonstrates a supplier’s reliability.

Cost Transparency

Competitive pricing paired with honest communication helps build long-term trust.

Benefits of Partnering with the Right Supplier

- Reduced Production Risks: High-quality suppliers minimize defects and delays.

- Enhanced Efficiency: Timely delivery keeps manufacturing lines running smoothly.

- Innovation Support: Collaboration fosters better designs and advanced solutions.

- Long-Term Cost Savings: Consistent quality reduces waste and increases efficiency.

Local vs. Global Stamping Parts Suppliers

| Factor | Local Supplier | Global Supplier |

|---|---|---|

| Lead Time | Faster turnaround | Longer due to logistics |

| Pricing | May be higher | Often lower for bulk orders |

| Support | Easier communication | Time zone and language barriers |

| Customization | More direct collaboration | May offer standardized solutions |

The choice depends on whether your business prioritizes speed and local support or global scale and pricing.

The Future of Stamping Parts Supply

The stamping industry is embracing new technologies to meet modern demands, including:

- Automation and Robotics: Enhancing precision and reducing labor costs.

- Sustainable Practices: Recycling and eco-friendly production methods.

- Smart Manufacturing: IoT integration for predictive maintenance and real-time monitoring.

- Advanced Materials: Development of alloys that balance strength and weight.

These trends signal that suppliers will continue to evolve, offering smarter and more efficient solutions.

How to Build a Strong Supplier Relationship

- Communicate Clearly: Share precise specifications and deadlines.

- Conduct Regular Audits: Ensure consistent adherence to quality standards.

- Invest in Long-Term Contracts: Stable partnerships lead to better service and pricing.

- Collaborate on Design: Involving suppliers early in the process improves final product quality.

Conclusion

A dependable stamping parts supplier is more than a provider—they are a strategic partner who ensures quality, efficiency, and scalability in your business operations. From automotive to healthcare and beyond, stamped components form the foundation of countless products, and the right supplier guarantees they meet the highest standards.

In an industry where precision and reliability are non-negotiable, building strong partnerships with experienced suppliers is the key to long-term success. By choosing wisely, businesses can secure not only quality components but also a competitive advantage in today’s fast-paced manufacturing world.