With the increasing popularity of modern homes and smart devices, tubular motors are becoming an indispensable core component. They are popular for their compact design, stable performance, and wide range of applications. Whether it’s rolling shutters, blinds, or smart sunshade systems, tubular motors can be found everywhere. They not only enhance ease of use but also add a sense of technology and comfort to any space.

With the rapid development of smart homes, people’s demand for quality of life and convenient operation is increasing, and the advantages of tubular motors are becoming increasingly prominent. They are quiet, easy to install, and can be integrated with smart systems like remote controls and mobile apps, providing users with an efficient and user-friendly experience. If you’re looking for more information and practical advice about motor tubulars, read on.

What Is a Tubular Motor?

A tubular electric motor is a small, specially designed cylindrical motor, named for its resemblance to a tube. It’s commonly installed inside devices that require rolling or raising/lowering, such as blinds, awnings, and projection screens. Its rotation drives the tubular shaft, enabling the lifting, opening, closing, or retraction of these devices.

This motor is compact, quiet, and long-lasting, and its concealed installation design ensures a discreet aesthetic. It can also be used with remote controls, wall switches, and even smart home systems for automation and remote control. Simply put, a tubular electric motor is a core power unit that transforms traditional manual operation into electric, intelligent control.

For example, Jiecang’s Rechargeable Motors-5V-USB are extremely energy-efficient, featuring a low standby power design and a runtime of 4-6 months on a full charge. They are also easy to install, powered by a built-in battery, and utilize silent technology and a patented silent motor design, resulting in an operating noise level of less than 32dB. Stall protection ensures safety and prevents damage, extending their service life and reducing the risk of accidents.

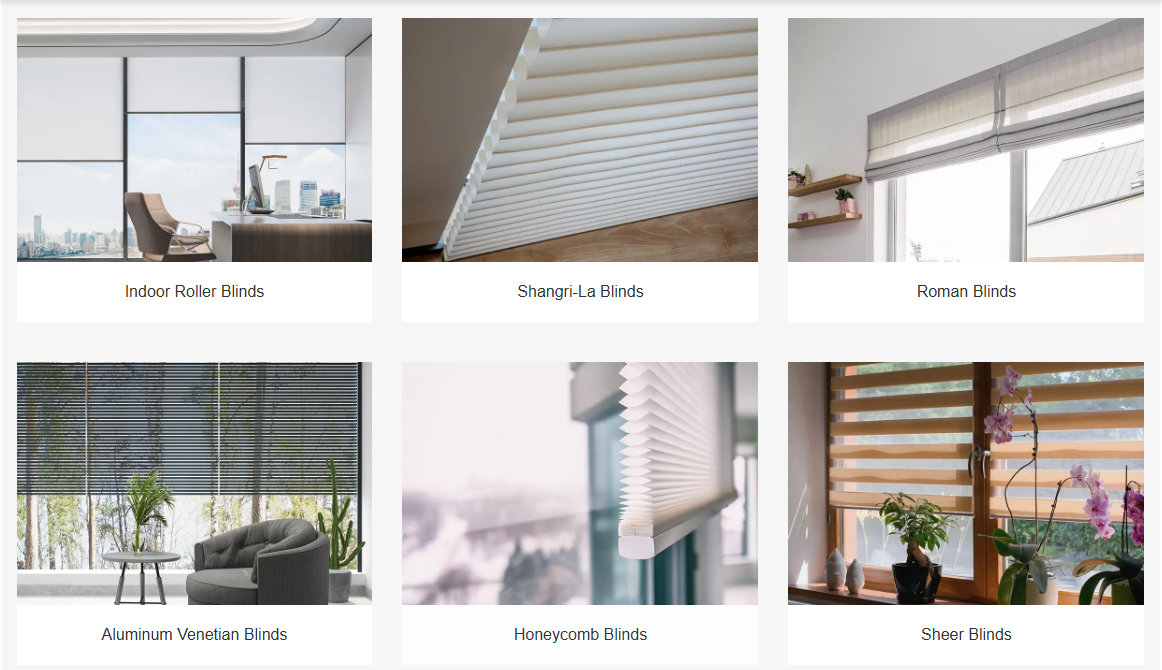

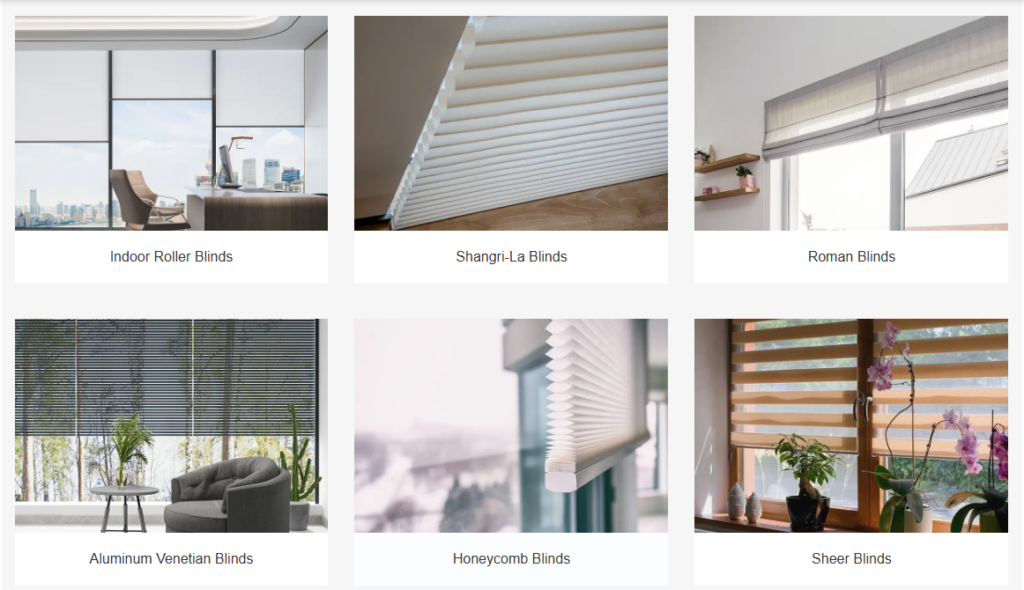

This tubular electric motor is also environmentally friendly, equipped with a solar panel. The system draws its operating energy from the sun, eliminating the need for regular motor charging. Suitable for indoor roller blinds, Shangri-La blinds, Roman blinds, aluminum Venetian blinds, Honeycomb blinds, and sheer blinds.

What Is a Tubular Linear Motor?

A tubular linear motor is a special type of linear motor. Its stator and mover are designed as cylindrical tubular structures, hence its name. Unlike traditional rotary motors, it does not require mechanical conversion such as gears or lead screws. Instead, it directly converts electrical energy into linear motion, achieving efficient, fast, and precise linear drive.

A tubular linear motor typically consists of a stator (coil windings) on the outside and a mover (a cylindrical structure with permanent magnets) on the inside. When current passes through the stator coils, it generates electromagnetic force that propels the mover in a linear direction. Because it eliminates intermediate transmission links, it offers low friction, high efficiency, and superior speed and positioning accuracy compared to traditional mechanisms.

Tubular linear motors are commonly used in automation equipment, CNC machine tools, semiconductor production, medical equipment, and logistics transmission systems, and are particularly well-suited for applications requiring high speed, high precision, and rapid response.

Advantages of Tubular Motors

1. Compact size and discreet installation. The tubular design fits directly into the roller tube, taking up no extra space and maintaining an aesthetically pleasing overall appearance.

2. Convenient operation. It can be controlled with a remote control, wall switch, or mobile app for effortless intelligent operation.

3. Stable operation and low noise. The well-designed motor delivers smooth and quiet operation, ensuring no disruption to daily life or rest.

4. Long lifespan and easy maintenance. High-quality components ensure durability and require virtually no maintenance.

5. High safety. Select models feature overload protection and blockage stop to prevent damage and potential safety hazards.

6. Versatile application. Suitable for home curtains, office blinds, and commercial rolling doors.

Key Considerations for Choosing a Tubular Motor

1. Load Capacity. Select the appropriate motor torque and power based on the weight and size of your rolling shutter, curtain, or awning to avoid unstable operation due to insufficient load.

2. Compatible Size. Confirm that the motor diameter matches the pipe diameter. Different motor tubular models are compatible with different roll-up pipe specifications.

3. Control Method. Options include wall switches, remote controls, smart apps, or integration with smart home systems. It is recommended to choose models that are compatible with multiple control options.

4. Operating Noise. For spaces requiring high levels of quiet, such as bedrooms and studies, a silent motor tubular should be selected.

5. Safety Protection. Pay attention to features such as overheating protection, overload protection, and stop-on-resistance protection to enhance safety and longevity.

6. Brand and Customer Service. Choose a reputable brand with comprehensive customer service to ensure consistent quality and prompt resolution of any issues. We recommend Jiecang.

7. Installation Ease. Prioritize designs that are easy to install and compact to save labor and time.

How to DIY a Tubular Linear Motor

1. Material Preparation

Permanent magnets.Strong rare earth magnets, evenly spaced along the tubular rotor.

Coil windings.Enameled wire wound around the stator core, forming a cylindrical coil array.

Tube housing.Aluminum alloy or engineering plastic can be used to ensure the rotor can move freely within.

Guide and support. Bearings, sliding sleeves, or guide rails ensure smooth linear motion of the rotor.

Power supply and drive circuit.A three-phase linear motor driver or an H-bridge circuit control circuit.

2. Construction Steps

Stator Winding. Arrange multiple winding coils at equal intervals on the tubular housing and secure them.

Motor Design. Embed or attach rare earth magnets to a cylindrical rod, with alternating magnetic poles.

Assemble the structure. Place the mover into the stator tube and use guides to maintain linear sliding.

Connect the drive circuit. Connect the stator coil to the motor driver module. By controlling the current phase and magnitude, electromagnetic force drives the mover back and forth.

3. Control and Debugging

Use a microcontroller (such as Arduino or STM32) to control the motor driver module, implementing PWM modulation and phase switching.

Add a position sensor (Hall sensor or photoelectric encoder) to improve positioning accuracy.

Adjust the current and frequency as needed to achieve different speeds and thrusts.