In today’s rapidly advancing industrial landscape, stainless steel piping systems play a crucial role in ensuring the efficient transportation of fluids, gases, and other materials. Among these systems, spiral weld stainless pipes have emerged as one of the most versatile and reliable solutions. Known for their strength, durability, and adaptability, these pipes are widely used in multiple sectors ranging from construction and water supply to oil and gas transport. Their ability to handle high pressure and resist corrosion makes them a preferred choice for demanding industrial environments.

What Is a Spiral Weld Stainless Pipe?

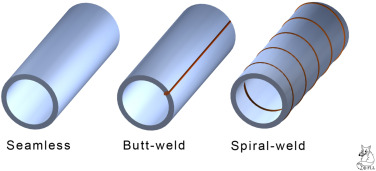

A Spiral Weld Stinless Pipe is manufactured by forming a continuous strip of stainless steel into a spiral shape and welding the edges together along the seam. This unique helical welding process allows for the creation of pipes with larger diameters, excellent structural integrity, and uniform strength. The spiral design distributes stress evenly across the pipe, ensuring reliable performance under varying pressure and environmental conditions. For high-quality stainless steel piping solutions, you can explore the advanced fabrication options available at Spiral Weld Stinless Pipe, where industry-leading standards and engineering precision come together to meet diverse industrial requirements.

Key Advantages of Spiral Weld Stainless Pipes

Spiral welded stainless pipes are designed to provide maximum efficiency and performance. Below are some of their most significant advantages in industrial use.

1. Exceptional Strength and Stability

The spiral welding process creates a strong, uniform seam that enhances the overall strength of the pipe. This design enables the pipe to withstand internal and external pressure, making it suitable for large-scale fluid transport systems and high-stress industrial applications.

2. Superior Corrosion Resistance

Because they are made from high-grade stainless steel, these pipes naturally resist corrosion caused by moisture, chemicals, and harsh environmental exposure. This quality ensures long service life, reduced maintenance costs, and consistent performance in industries where corrosion is a critical concern.

3. Cost-Effective Manufacturing

Compared to longitudinally welded pipes, spiral welded pipes use narrower steel strips, which helps optimize raw material utilization and lower production costs. Additionally, the continuous manufacturing process allows for faster production speeds without compromising quality.

4. Flexibility in Size and Length

The spiral forming process allows for the manufacture of pipes in a wide range of diameters and lengths. This flexibility makes them ideal for custom engineering projects where standard pipe sizes may not meet specific requirements.

5. Excellent Pressure Distribution

The spiral weld configuration distributes stress evenly across the entire surface, reducing the likelihood of failure due to concentrated stress points. This makes them highly reliable in applications involving high internal pressures or heavy loads.

6. Smooth Interior Surface

The inside surface of a spiral welded stainless pipe is smooth and free from defects, which minimizes frictional losses and prevents buildup of deposits. This characteristic is particularly advantageous in industries where maintaining fluid purity and flow efficiency is essential.

Industrial Applications of Spiral Weld Stainless Pipes

Due to their unique properties and construction, spiral welded stainless pipes are used in a wide variety of modern industries. Their combination of strength, flexibility, and corrosion resistance makes them indispensable in several applications.

1. Oil and Gas Industry

In the oil and gas sector, these pipes are used extensively for the transportation of crude oil, natural gas, and petroleum products. Their ability to withstand high pressure and extreme environmental conditions ensures safety and reliability in long-distance pipeline systems.

2. Water Supply and Sewage Systems

Spiral welded stainless pipes are commonly used in municipal and industrial water supply networks. Their corrosion resistance ensures that the water remains uncontaminated, while their strength makes them suitable for underground installations and high-pressure flow systems.

3. Construction and Infrastructure

In construction, spiral welded pipes are used as structural supports, piling, and foundation reinforcements. Their robust design provides excellent load-bearing capacity, making them ideal for bridges, buildings, and industrial facilities.

4. Chemical and Processing Plants

Chemical industries rely on stainless steel pipes to handle aggressive fluids and corrosive substances. The spiral welded variant provides additional strength and durability, reducing the risk of leakage or contamination in sensitive processing environments.

5. Marine and Offshore Applications

In marine environments, corrosion resistance is a top priority. Spiral welded stainless pipes are perfect for use in offshore platforms, seawater desalination plants, and shipbuilding, where they resist both saltwater corrosion and mechanical stress.

6. Power Generation

Power plants, including thermal and nuclear facilities, use spiral welded stainless pipes in systems that carry steam, water, and other fluids at high temperatures and pressures. Their stability and resilience ensure uninterrupted operation in critical power generation systems.

Environmental and Operational Benefits

The durability and recyclability of spiral welded stainless pipes contribute to sustainable industrial practices. Stainless steel can be fully recycled, reducing waste and supporting eco-friendly manufacturing processes. Additionally, the pipes require minimal maintenance, which lowers the operational costs and downtime over their lifecycle.

Conclusion

In the ever-evolving landscape of modern industry, the Spiral Weld Stinless Pipe has established itself as a cornerstone of reliable and efficient infrastructure. Its superior strength, excellent corrosion resistance, and adaptability across applications make it indispensable in sectors such as oil and gas, construction, and water management. By combining engineering precision with long-term performance, these pipes continue to drive innovation and sustainability in global industrial operations. Understanding their advantages and applications helps engineers, manufacturers, and project managers make informed decisions for building durable and efficient piping systems that stand the test of time.